Quality Leadership at SENS: A commitment to Excellence

Quality is a core value at SENS, essential to our success and to the mission-critical operations of our customers. Our products support vital infrastructure, including data centers, utilities, oil and gas, cable/telecom/wireless and hospitals.

Recognizing the critical nature of these applications, we are committed to continuous improvement in quality and delivery performance, striving for zero defects while maintaining cost efficiency. Our quality policy emphasizes maximizing customer satisfaction by addressing the largest sources of defects and waste, delivering reliable and efficient solutions for essential industries.

Ensuring Reliability in Mission-Critical Applications

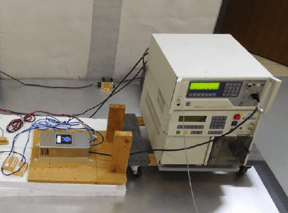

Downtime is intolerable for mission-critical applications. To ensure lasting performance under extreme conditions, SENS employs a “worst-case” design approach combined with extensive testing.

What is worst-case design?

SENS uses worst-case design to ensure all components stay within stress limits - even under the most extreme conditions. We augment laboratory testing with comprehensive computer simulations to validate various “corner cases” and field conditions that are impossible to fully replicate in a lab.

Why is worst-case design essential?

This rigorous approach guarantees that SENS products remain dependable in harsh environments, offering a low total cost over time. In contrast, custom-built or consumer-grade products rarely meet the same standards of reliability, as they lack standardized, well-documented design practices.

How does worst-case design benefit customers?

By prioritizing worst-case design, SENS creates standardized, richly featured products that boast lower failure rates than many conventionally engineered alternatives.

SENS products are built to survive and perform, offering clients dependable, standardized solutions at affordable prices.

Compliance with Codes & Quality Standards Across All Applications

Certifications from trusted third parties indicate that a manufacturer meets established standards for quality, safety, survivability, electromagnetic compatibility, and performance. While standards compliance doesn’t guarantee success in every application, third-party certifications show a manufacturer’s commitment to excellence, helping reduce risk for buyers. Here’s how SENS demonstrates quality leadership:

|

Certification |

Description |

|---|---|

|

ISO 9001 Quality System |

Since 1996, SENS has maintained ISO 9001 certification, reflecting our commitment to quality and operational excellence. Independent auditors regularly assess our internal controls across all functions, including self-audits and corrective action systems. Unlike firms claiming only "ISO-compliance," SENS meets rigorous third-party scrutiny to achieve certified status. |

|

UL Listing |

Nearly all SENS products are UL listed to meet stringent safety standards set by Underwriters Laboratories (UL), known for comprehensive enforcement. Many engineers and AHJs (Authorities Having Jurisdiction) prefer UL listing over other certifications like CSA or ETL, despite all being legally recognized under the Nationally Recognized Test Laboratory (NRTL) standards. |

|

American Bureau of Shipping (ABS) Approval |

SENS’s EnerGenius IQ and MicroGenius chargers hold ABS type approval, meeting U.S. Coast Guard standards with an optional drip shield. ABS certification allows SENS to ship immediately upon passing factory tests, streamlining delivery without waiting for additional ABS auditor approvals. Additional certificates include the SENS MG2 ABS Type Approval and the SENS MG S2/S4 ABS Type Approval. |

|

Electromagnetic Compatibility (EMC) |

Tested in third-party labs, SENS chargers meet and exceed standards for radio frequency emissions and have immunity to electrical fast transients, electrostatic discharge, and lightning resistance. Most models comply with ANSI and European standards for enhanced electromagnetic compatibility. |

|

Seismic Survival |

SENS understands that mission-critical infrastructure, such as power services, water utilities, and hospitals, must remain operational during severe earthquakes. SENS’s battery chargers are certified to IBC and OSHPD seismic standards, ensuring dependable performance in seismic events. |

ISO 9001 Certification: Commitment to Quality

ISO 9001 is a globally recognized quality management system standard that emphasizes key principles like customer focus, top management involvement, process efficiency, and continual improvement. By adopting ISO 9001:2015, SENS ensures consistency and a disciplined, process-driven approach to quality enhancement across our stored energy systems and critical power solutions.

Why ISO 9001 Matters for SENS and Our Customers

Two key distinctions of ISO 9001 compared to non-ISO quality systems are formal audits and a robust corrective action system. These components guarantee that:

- Controlled Processes: Regular internal and third-party audits verify that SENS’s processes remain in control and management actively reviews outcomes.

- Disciplined Problem-Solving: The formal corrective action system mandates cross-functional root cause analysis, leading to effective solutions for complex challenges.

As an early adopter since 1996, SENS has maintained its ISO 9001 certification, exemplifying our dedication to quality and operational excellence.

Maximizing Value with Lean Production at SENS

Lean manufacturing is one of the most efficient systems for transforming knowledge, materials, and labor into high-quality finished goods. At SENS, our lean production approach ensures superior customer value by focusing on four key areas:

- Quality: The lean system embeds quality checks throughout the assembly process, reducing the risk of defects and ensuring the reliability of our stored energy systems.

- Delivery: With an optimized supply chain and streamlined assembly, SENS achieves short lead times without needing to stock finished goods, ensuring timely delivery.

- Cost: Enhanced quality and faster throughput lower production costs, enabling SENS to deliver high-spec, reliable products at competitive prices.

- Continuous Improvement: At the heart of lean manufacturing is continuous improvement. We incorporate customer feedback into our processes, dedicating time and resources to refining both our products and service.