BATTERY MONITORING SYSTEMS

Remote Monitoring for Reliable Power

Battery Monitoring Systems

Battery Monitoring for Mission Critical Infrastructure

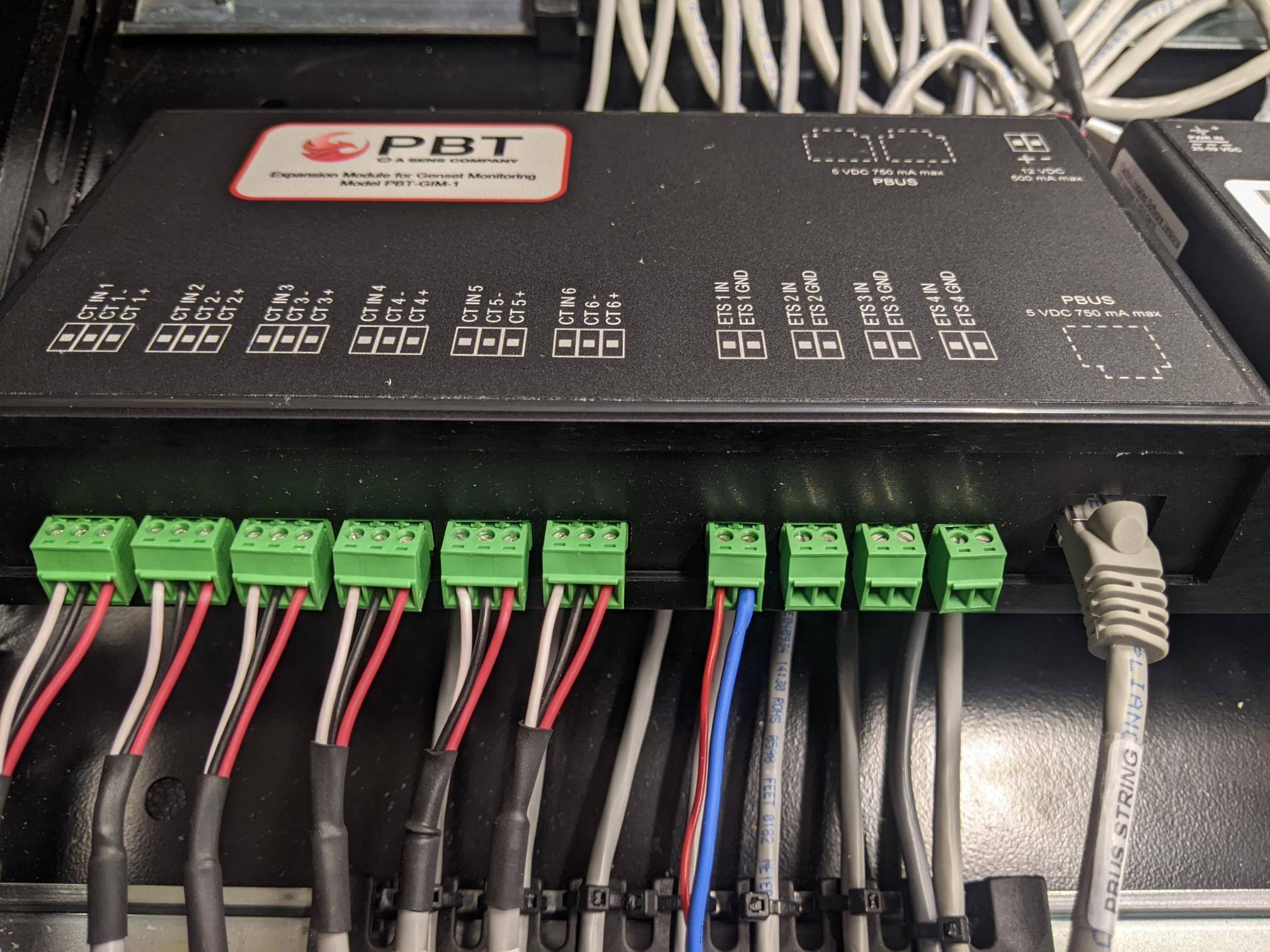

Manufactured by Phoenix Broadband Technologies (PBT), a SENS company

Mission-critical services and critical infrastructure facilities require reliable, uninterruptable power. For these applications, it is common to have backup battery plants that can run the equipment at the site for hours, or at least until a backup generator is ready to take the load.

Batteries are a weak link in any mission-critical power system and must be monitored & proactively maintained in order to obtain the rated service life and the longest possible run times.

Remote battery monitoring can save maintenance costs, predict impending battery failures, extend battery service life, and improve overall site availability.

The PBT battery monitoring systems have the added benefit of being comprehensive facilities monitoring systems, extending monitoring and control capabilities to generators, chargers/inverters, HVAC systems, and building monitoring.

START A CONVERSATION

Automating Remote Battery Monitoring

Traditional manual testing of batteries and generators is time-consuming and expensive, resulting in only a few data points being collected yearly.

In addition, periodic manual measurements produce variable data, depending on how the technician makes the measurements and the type of instrument used.

This measurement data is seldom data-based in a form that can be “mined” for trends, so manual testing is not as useful or valuable as it could be. Automated remote measuring and monitoring systems can provide continuous and repeatable test data with thousands of data points per year.

These data records can be logged and mined for indications of equipment that needs maintenance or replacement, trends that predict future equipment failures, and environmental parameters that might affect equipment operation or life expectancy.

PBT Battery Monitoring Systems

Most Flexible

No proprietary control unit, no complex battery interface wires

Most Scalable

Small intelligent sensors mounted to each battery deliver individual battery-specific information

Long life, no maintenance

Mechanical and electrical connections to the battery are only made once at installation time

Freedom of Software

Hardware and software decoupled allowing you the choice of software

have questions or need help?

The SENS team is here to help you through your battery monitoring journey. If you have questions or need help, reach out and start a conversation.

.png?width=500&height=500&name=SENS_Product_Catalog%20(1).png)