.png?width=576&height=512&name=Frame%20(9).png) User Manuals

User Manuals

Have Questions?

Our SuperTorque 8Z experts are here to help.

SuperTorque 8Z Engine Starting System

SENS SuperTorque 8Z Engine Starting System solves the #1 problem with emergency generators: starting battery failure. Unless lead-acid starting batteries on gensets are replaced every one to three years, they fail suddenly, without warning. Even if replaced this often, they sometimes explode.

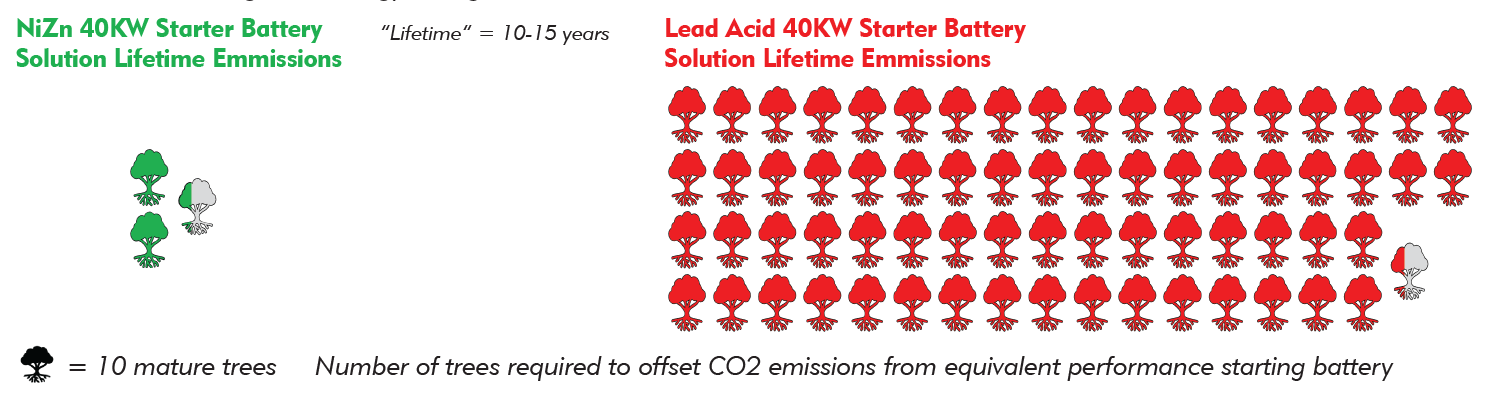

Offering a full 10-year warranty, the heart of SuperTorque 8Z is the high-performance nickel-zinc (NiZn) battery. Like other nickel-based batteries, NiZn is very stable and long-lived. SuperTorque 8Z is also the sustainable choice. Lifetime GHG emissions from NiZn batteries in SuperTorque 8Z are 96% lower than for a comparable performance lead-acid battery.

Solves Genset Starting Problems. Guaranteed.

- Super powerful, safe NiZn battery – contains no lithium or hazardous materials. Air shippable!

- 10-year full warranty – say goodbye to regular battery replacements

- No sudden failure – unlike lead-acid, which typically fails suddenly and without warning

- More power, less space – 75% smaller than comparable lead-acid – including charger!

- Long life, no maintenance – cuts ongoing cost of truck rolls and electrolyte top-ups

- Sustainable – no hazardous materials; 96% lower lifetime GHG emissions than lead-acid

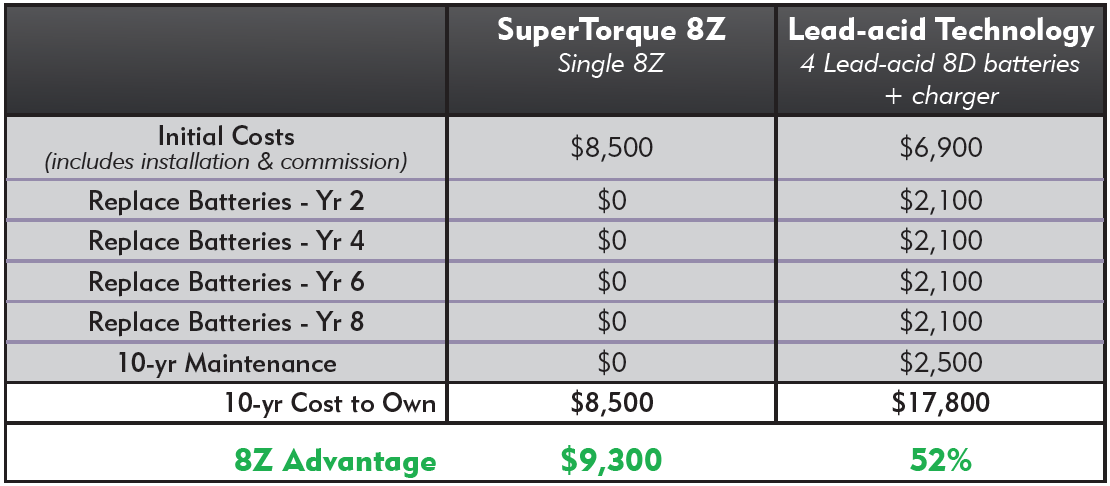

- Lowest total cost of ownership (TCO) – greater than 50% lower cost over ten years than lead-acid

More power, less space

The 8Z is 75% smaller than equivalent lead-acid starting options

10-year full warranty

Eliminates regular battery replacements.

Long life, no maintenance

Cut the ongoing expense of truck rolls and electrolyte top-ups

Safe shipping

NiZn batteries contain no lithium or hazardous materials for safe air shipping

Lower emissions

Approximately 96% lower lifetime carbon emissions

Increased efficiencies

More energy efficient to manufacture, transport and recycle

Less labor

There’s no need for regular replacement or periodic watering

No sudden failure

Highly reliable throughout the lifespan and rarely fails without warning

8Z Data Sheet

- Get Started

- Benefits

- More Power

SuperTorque 8Z

Genset Starting System

Super High-Performance Battery + Integrated Charger System

Solves Genset Starting Problems. Guaranteed.

Super powerful, safe NiZn battery - contains no lithium or hazardous materials. Air shippable!

- 10-year full warranty - say goodbye to regular battery replacements

- No sudden failure - unlike lead-acid, which typically fails suddenly and without warning

- More power, less space - 75% smaller than comparable lead-acid – including charger!

- Long life, no maintenance - cuts ongoing cost of truck rolls and electrolyte top-ups

- Sustainable - no hazardous materials; 96% lower lifetime GHG emissions than lead-acid

- Lowest total cost of ownership (TCO) - greater than 50% lower cost over ten years than lead-acid

Solves genset starting problems for good SENS SuperTorque 8Z Genset Starting System solves the #1 problem with emergency generators: starting battery failure. Unless lead-acid starting batteries on gensets are replaced every one to three years they fail suddenly, without warning. Even if replaced this often they sometimes explode.

Offering a full 10-year warranty, the heart of SuperTorque 8Z is the high-performance nickel-zinc (NiZn) battery. Like other nickel-based batteries, NiZn is very stable and long-lived.

SuperTorque 8Z is also the sustainable choice. Lifetime GHG emissions from NiZn batteries in SuperTorque 8Z are 96% lower than for a comparable performance lead-acid battery.

Offering superb reliability, better than a 50% TCO advantage over lead-acid batteries and a vastly smaller environmental footprint, SuperTorque 8Z is the overwhelming best choice for genset starting energy storage.

Long-life, super high-rate battery

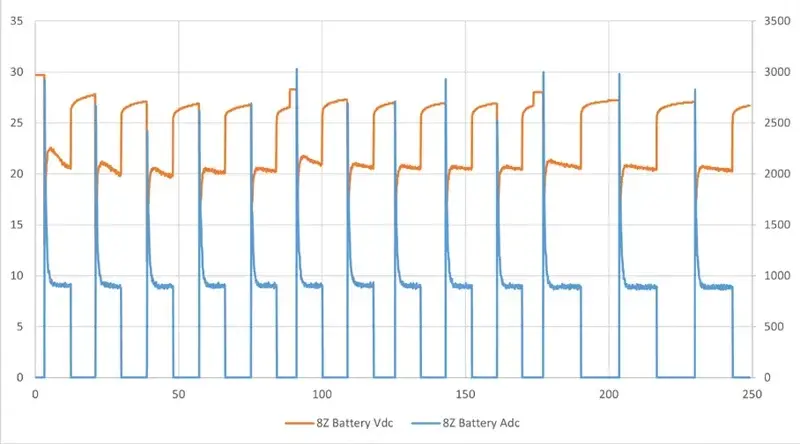

Well proven in data center UPS, the super high-rate NiZn battery combines phenomenal high-rate performance with great endurance. The inherent advantage of NiZn technology is that battery voltage changes little with state of charge. Even at a low state of charge SuperTorque 8Z still delivers powerful starting performance. In contrast, voltage of lead-acid batteries quickly drops too low to crank an engine, leaving most of the lead-acid battery’s capacity stranded in the battery.

Chart of ONE SuperTorque 8Z cranking 70L diesel genset 13 times without recharge – still going strong at the end!

Embedded MicroGenius 2 charger

Inside SuperTorque 8Z is a reliable SENS charger, optimized for NiZn charging. Factory installation means no separate charger installation or wiring. The charger accepts universal AC input (100-240 volts, 50 or 60 Hz) via either IEC 320 connector and cord or hardwired conduit.

The clear sustainable choice

The SuperTorque 8Z NiZn battery results in 96% lower lifetime carbon emissions than lead-acid starting batteries. NiZn technology is much more energy efficient to manufacture, transport, and recycle than lead-acid. It weighs less. Its long service life retires the need for regular replacement. There is no periodic watering required.

SuperTorque 8Z uses no hazardous materials. The on-board MicroGenius charger is up to 93% efficient and consumes less than 3 watts at idle. SuperTorque 8Z is the most sustainable genset energy storage solution available.

More power in less space

A single 24-volt SuperTorque 8Z system, the size of one 12-volt 8D battery, replaces up to four 8D lead-acid starting batteries and a premium charger.

Sizing considerations

The primary limit governing how big an engine one SuperTorque 8Z will start is depth of voltage drop during the initial ~200 milliseconds “locked rotor” condition at the beginning of the crank cycle. Most engine control computers (ECU) on 24V systems tolerate voltages down to12 volts. Larger current draw at locked rotor reduces available voltage at the starter.

One 24-volt SuperTorque 8Z will crank diesel engines with two starters up to 70 liters displacement. The number of starters is relevant. For any given displacement engine, more starter motors typically means higher current during the locked rotor condition.

SuperTorque 8Z TCO advantage

Lead-acid batteries require regular maintenace and replacement every 1-3 years. The table below illustrates the significant financial benefit of SuperTorque 8Z’s much longer life.

Assumptions:

-

Lead-acid batteries modeled at $275 each.

-

Labor for battery replacements based on $125/hour, 2-person team, four-hour job ($1000 total).

-

Lead-acid battery maintenance includes check and water every six months. Assume 1 hour @ $125/hr ($250/year).

-

The Ni-Zn battery is maintenance-free. It requires no electrolyte check or top-up.

Detailed Specs

This specification defines an engine starting system consisting of integrated internal nickel-zinc battery bank, dedicated charger, controls, and communications. System shall provide reliable engine starting power to industrial engines.

2.1. Safety Agency Standards

2.1.1. Power components are UL Listed/Recognized for the United States (ULUS) and Canada

(CUL)

2.1.2. NFPA 70

2.2. FCC Standards Emissions

2.2.1. 47-CFR-15 (FCC Part 15) Class B

2.3. Electrical Transient

2.3.1. ANSI/IEEE C62.41, EN 61000-4-12 on power terminals, IEC 61000-6-5 and ANSI/IEEE

C37.90

2.4. Vibration and Shock

2.4.1. Swept Sine (EN60068-2-6): 4G, 18-500 Hz, 3 axes. Random: 20-500Hz, .01G2

/Hz. Shock: EN 60068-2-27 (15G)

2.5. Electrical Transient

2.5.1. ANSI/IEEE C62.41 & EN 61000-4-12 on power terminals

2.6. European Union (CE)

2.6.1. EMC: 2014/30/EU (EN 61000-6-2 and EN 61000-6-4)

2.6.2. LVD: 2014/35/EU (EN 60335-1 and EN 60335-2-29)

2.6.3. RoHS: 2011/65/EU (EN 50581)

2.7. Seismic

2.7.1. Seismic: Rigid base mount; max Sds of 2.5g. Certified to IBC 2000 - 2021 and California Building Code 2007 – 2021.

3.1. The AC input voltage range shall be 90-265VAC.

3.2. The AC input frequency range shall be 47-63Hz.

3.3. Charging system efficiency shall be 90% or greater.

3.4. The charging system shall provide active power factor correction. The power factor shall be at

least 0.95 or greater at maximum charging power.

3.5. Supplementary overcurrent protection fuse, transient protected to EN 61000-4-5 level 4

4.1. The internal battery shall be nickel-zinc chemistry.

4.2. The system shall be available in 12V and 24V models.

4.3. The onboard battery shall have a minimum capacity of 80Ah.

5.1. The onboard battery charger shall have custom charging algorithms specifically designed for use

with nickel-zinc batteries.

5.2. The charging algorithms shall be specifically approved by the nickel-zinc battery manufacturer.

5.3. Internal battery temperature charging compensation shall be standard.

5.4. The onboard battery charger shall be able to completely recharge the batteries within 8 hours.

5.5. The onboard battery charger shall have an output current of 12A minimum.

SuperTorque 8Z® Product

5.6. The charging ripple shall not exceed 30mV.

6.1. Output Current

6.1.1. Locked Rotor Performance (breakaway current condition)

6.1.1.1. The unit shall provide breakaway currents of 2000A or greater.

6.1.1.2. For 12V starting systems, the locked-rotor voltage shall not drop below 5.0VDC

during the locked-rotor condition.

6.1.1.3. For 24V starting systems, the locked-rotor voltage shall not drop below 10.0VDC

during the locked-rotor condition.

6.1.2. Engine Cranking Performance (rolling current condition)

6.1.2.1. The unit shall provide engine cranking (rolling) currents of up to 1000A.

6.1.2.2. For 12V starting systems, the cranking voltage shall not drop below 9.5VDC during

cranking.

6.1.2.3. For 24V starting systems, the cranking voltage shall not drop below 19.0VDC during

cranking.

6.1.3. Shall meet NFPA 110 engine cranking performance requirements (note: NFPA 110 (2022) requirement that the batteries must be either lead-acid or nickel-cadmium excepted).

7.1. The engine starting system shall support connection in parallel with two or more systems for increased starting capacities and redundancy.

7.2. The engine starting system shall support integration with Best Battery Selectors or battery isolators.

7.3. The engine starting system shall be useable in conjunction with lead-acid, nickel-cadmium or other battery types when coupled through a best battery selector.

8.1. The engine starting system shall operate from -10°C to 55°C.

8.2. The engine system shall be stored in temperatures from -20°C to 60°C.

8.3. Ingress Protection

8.3.1. The ingress protection shall be IP22, NEMA 3R, and UL “Rainproof”

8.3.2. Charger shall have internal ingress protection such that all AC and communications connections are non-exposed and protected from incidental jarring.

8.4. The engine starting system shall operate in humidity levels ranging from 0% to 95%, noncondensing.

8.5. The engine starting system shall operate at full specification from 0 to 13,000 ft, or 0 to 4000m above sea level.

8.6. The engine starting system shall be cooled via natural convection with no internal fans.

9.1. Floor mount brackets for bolted mounting

9.2. SAE Battery Posts for DC connections

9.3. Keypad user interface and display

9.4. Communication

9.5. Field wiring kit including

10.1. The base level user interface shall provide a multicolor LED panel showing system status.

10.2. The optional level user interface shall include a backlit LCD displaying plain language text, a multicolor LED panel showing system status, and a user control panel.

10.2.1. System shall be equipped with a 1% accuracy meter for indicating AC input and DC output voltage and 1% accuracy meter for indicating DC charging current.

10.3. User interface shall ensure that users cannot change settings that would damage the battery.

11.1. Standard Communications

11.1.1. (2) Form-C Alarm Relay Contacts

11.1.1.1. Alarm relay contacts shall be customizable to support customer-specific alarm

combinations and setpoints.

11.1.2. USB-C

11.1.2.1. A Setup Utility shall be available providing a custom configuration and diagnostics software utility that runs on a Windows PC via USB-C or an ethernet port.

11.2. Optional Communications

11.2.1. J1939

11.2.2. Modbus RS-485

11.2.3. Modbus TCP/IP

11.2.4. Ethernet

11.3. Custom alarm profiles shall be supported which allow the alarm relay and communications

settings to be assigned at the factory according to the specific customer requirements.

11.4. Alarms

11.4.1. Any alarm indication shall cause plain language text to appear on the LCD and change appropriate LEDs. Normal LED indication shall be green. Alarm LEDs shall be red. Warning LEDs shall be amber. Multiple alarms result in the relevant LEDs changing color and multiple alarm message screens on the LCD. Alarm status shall also be available via communication interfaces.

11.4.2. The following alarms shall be provided, and shall be made assignable to any relay:

11.4.2.1. AC Line Failure

11.4.2.2. High DC Voltage

11.4.2.3. Battery on Discharge

11.4.2.4. Low DC Voltage

11.4.2.5. Battery End of Discharge

11.4.2.6. Charger Fail

11.4.2.7. Over Voltage Shutdown

11.4.2.8. Invalid Settings

11.4.2.9. Thermal Foldback

11.4.2.10. Temperature Probe Fault

11.4.2.11. Current Limiting

11.4.2.12. Load Share Fail

11.4.2.13. DC Below Startup Voltage

11.4.2.14. High Battery Temperature

11.4.2.15. High Battery Temperature Shutdown

11.4.2.16. AC Voltage Low

11.4.2.17. AC Voltage High

11.4.2.18. AC Frequency Out of Range

11.4.2.19. Low Engine Crank

12.1. AC input connection shall be a locking-type IEC 320 C13 connector.

12.1.1. An optional UL Listed field terminable locking connector shall provide accommodation for hard wiring. Ordered separately.

12.2. An IEC 320 C14 AC output connection shall be provided for system paralleling.

12.3. Unit shall be supplied with AC input power cord. Locking-type, 8ft minimum length. IEC 320 C13 connection to unit, NEMA 5-15R plug connection to AC feeder.

12.4. The standard DC output connections shall be M8 threaded inserts.

12.4.1. The optional DC output connection shall be SAE battery posts.

12.5. The communications wiring shall be connected via pluggable field terminal blocks or RJ45 connections.

13.1. Enclosure construction shall be 1/8” 5052 aluminum.

13.2. Enclosure top surface shall be non-conductive.

13.3. Enclosure shall accommodate side cable conductor and conduit entry.

13.4. Unit weight shall not exceed 100lbs (45kg).

13.5. Enclosure shall not exceed 22in (l) x 12in in (w) x 11in (h).

13.6. Enclosure shall support the weight of a 300lb vertical load.

14.1. 10-year full replacement warranty shall be standard.

15.1. In order to meet evolving customer requirements, changes to the product and to this specification may be made without notice from time to time.

have questions or need help?

The SENS team is here to help. If you have questions or need help, reach out and start a conversation.

.png?width=512&height=512&name=Frame%20(10).png)